Ex-factory complete washing filling capping 3in1 water bottling machine fully set price $8500. Come with 6meter conveyor belt and motor. Most bottle water company first water filling machine to start bottled water business.

WHAT IS THE 12-12-1 BOTTLING MACHINE COST?

fob price $ 8500

What this price come with?

- 1 SET QS-12 Auto Bottle Washer

- 1 SETCY-12 Normal Pressure Filler

- 1 SET FXZ-1 Screw Capper

- 7 METER Conveyor Belt

- 1 SET Conveyor Motor

- 1 SET Empty Bottle Table

- 1 SET Finished Bottled Water Table

Water bottling machine linera type automatic accomplish whole process from washing, negative pressure, filling, settle cap, buckle cap till screw cap. It is the most bottle water company first water filling machine to start bottled water business.

Key Features:

- Linear Design: The machine operates in a linear fashion, facilitating a smooth and continuous flow of bottles through each stage.

- High Precision: Utilizes advanced technology for precise washing, filling, and capping, ensuring accuracy in production.

- Efficiency: Each station operates continuously without pausing, using a rotary mechanism.

- Reliability: Designed for reliable and consistent performance, minimizing downtime and ensuring a steady production flow.

This linear water bottling machine is an ideal solution for water bottling plants seeking efficiency, precision, and high-quality output. It streamlines the production process, making it a valuable asset for the bottled water industry.

What is the production capacity of the linear water bottling machine?

Its speed can reach 2000 bottles per hour. Mean 34 bottles per min. Its every machine still made use of rotation Technology. Every bottle respective washing filling capping do not need waiting .

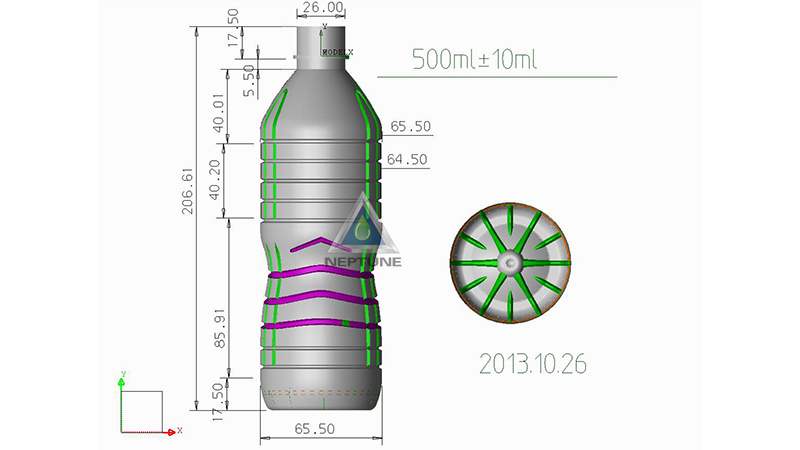

- 500ml Bottled Water: 2000 bottles per hour

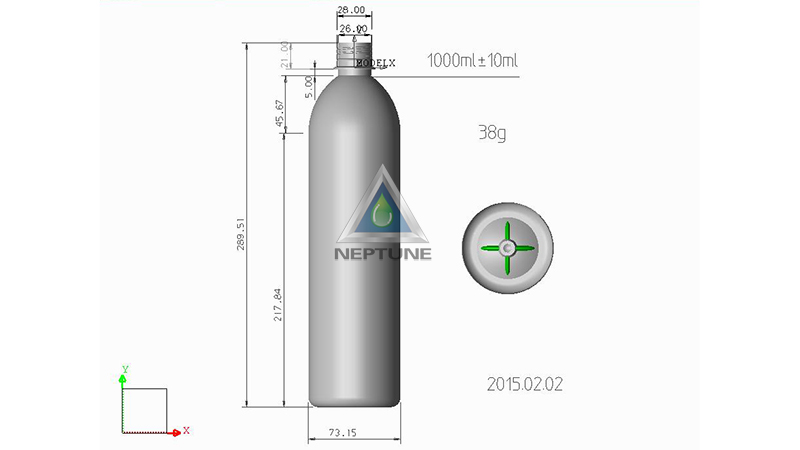

- 1500ml Bottled Water: 1000 bottles per hour

- 1000ml Bottled Water: 1300 bottles per hour

- 350ml Bottled Water: 2000 bottles per hour

Product Details:

| Driven type | Motor |

| Washing Valves | 12psc |

| Filling Valves | 12psc |

| Capping Valves | 1psc |

| Power | 2.5kw |

| Capacity | 2000Bottles/h |

| Filling Bottle Size | 200ml to 2000ml |

| Materials | Stainless steel |

| Voltage | 380v/3phase/50hz and 220v/3phase/60hz (Other need specially order) |

12-12-1 Water Bottling Machine Working process

1. Washing: The machine initiates the process with a thorough washing stage. Bottles are conveyed into the washing section, where they undergo a meticulous cleaning process to ensure hygiene and purity. This step is crucial for preparing the bottles for the subsequent stages.

2. Filling: After the washing stage, the bottles move seamlessly into the filling section. The machine employs precision technology to fill each bottle with the desired amount of water accurately. This ensures consistency and reliability in the filling process.

3. Capping: Upon completion of the filling stage, the bottles progress to the capping section. The machine precisely places and seals caps onto each bottle, ensuring a secure and airtight closure. This step is vital for maintaining the quality and integrity of the bottled water.

Is the machine adaptable to different cap & bottle sizes ?

Through change shape mold, It can adaptable to different shape and volume plastic bottle. Making it versatile for different production requirements.

- Bottle diamater range: 50mm to 100mm

- Bottle volume range: 200ml to 2000ml

If you have specific bottle size needs, the machine can be adjusted or customized accordingly to meet those specifications.

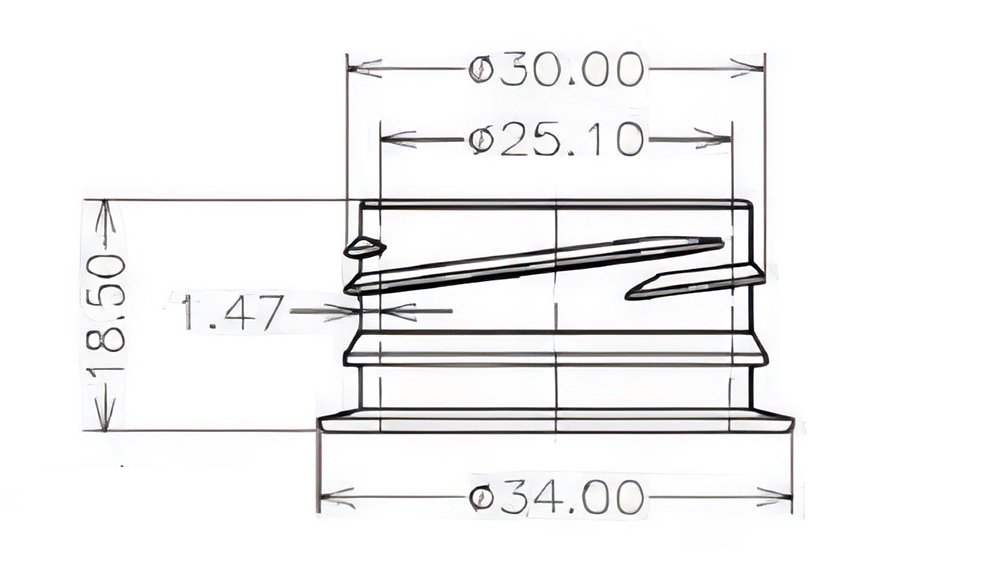

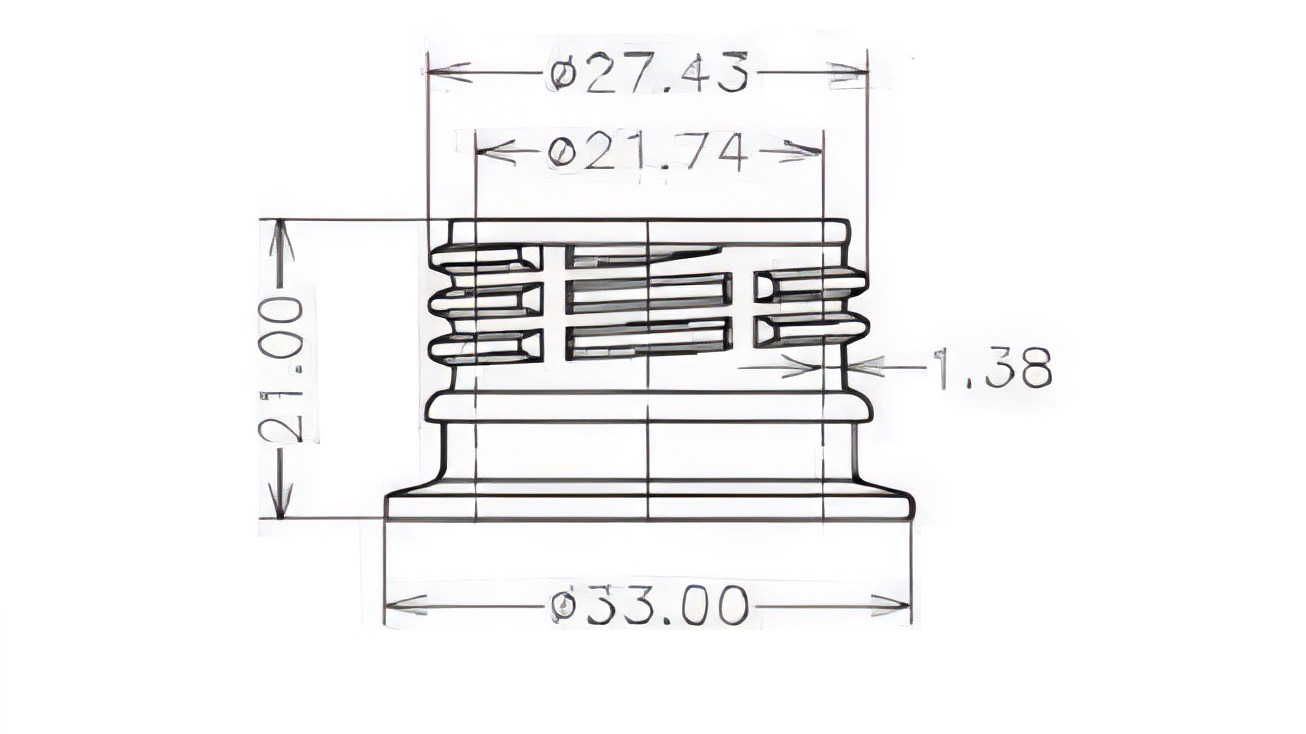

It is only fit screw type cap. It adaptable to different cap sizes. You can change the necessary spare parts to accommodate different cap sizes.

- 30mm cap, 28mm cap

- 30mm shorter cap, 28mm shorter cap

However, it’s important to note that changing cap sizes may require some adjustments and additional spare parts. It’s recommended to consult with NEPTUNE MACHINERY to ensure that you have the appropriate spare parts and information for adapting the machine to different cap sizes.

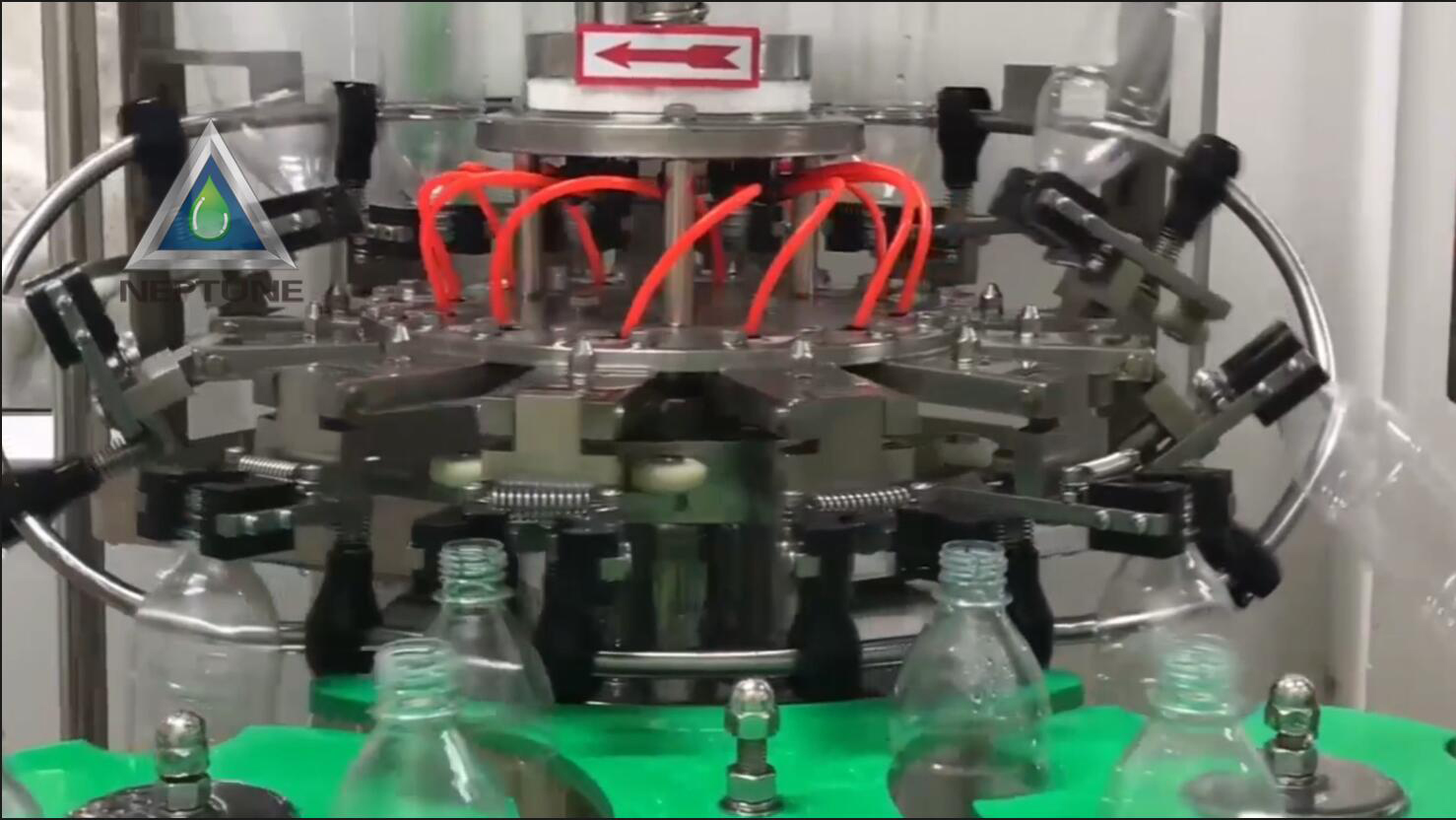

Rinser, Filler, Capper Unit

QS-12 Auto Bottle Rotary rinser

It is one of the most versatile medium speed bottle rinser. It can use in an lot industry like water and beverage. It is designed to effectively internally washing up to 3,000 small bottles per hour or 50 bottles per minute. It’s ideal for rinsing bottles ranging in size from 12oz (335ml) up to 2liters. It is easy change bottle size through change an shape mold. Only need an few minutes and do not need else tool.

CY-12 Normal Pressure Rotary Filler

CY-12 Normal Pressure Filler is an automatic system. Its capacity of production is 3,000 bottles per hour. It can provides maximum versatility to keep pace with the demands of your operation. It is designed and built to operate multiple shifts with a minimum of the maintenance and does not requir highly skilled operators.The stae-of-the-art design and components offer maximum performance,reliability and versatility to fill from 335ml up to 2liter bottle.

FXZ-1 Rotary Screw Capper

is an bottle capping systems. At first, the filled water bottle go into the the build-in bottles spacing unit. The bottle sapcing unit will precise and constant bottle spacing. The correct spaceing ensures that every caps are applied consistently with the most accurate alignment possible. The worker need moved an box cap to the cap hopper for cap appliation prepare.

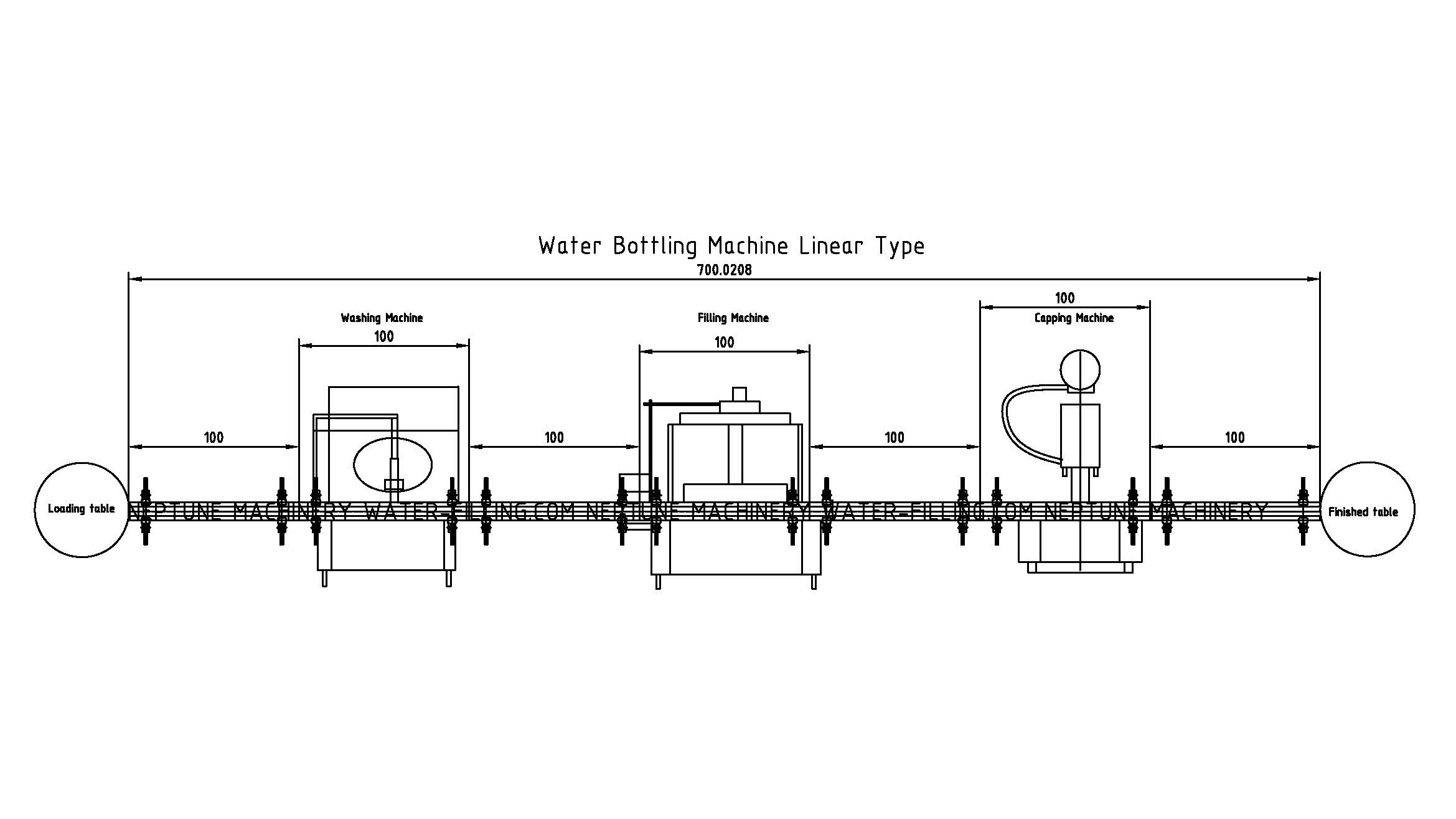

Layout of the water bottling machine production line

Firstly, it need workers insert plastic bottle on the conveyor belt or unscrambler. If you want use unscrambler which need additional purchase.

Secondly, the conveyor belt will conveyor the empty plastic bottle to washing part machine. The washing part machine will catch the mouth of the plastic bottle. Then filp the plastic bottle 180degree and pushing pure water into the inside of the plastic bottle. It total have 12psc washing head.

Thirdly, the conveyor belt will conveyor the washing well bottle to the filling machine, The filling machine will filler pure water into the plastic bottle. And filler just enough well water according setting. It have 12psc filling head.

Fourthly, the conveyor belt will conveyor the filler well bottle water to the capping part machine, The capping machine just have one capper head. It will automatic screw an cap on the bottled water and finished bottling process. The final bottled water is an completely bottled water without label only.

Video

It is widely used for filling all kinds of plastic or glass bottles of gas containing drink or no gas drink.It has the advantages of reasonable mechanical structure, stable in moving, good in feature, easy operation and maintenance, widely used.

- Its advantage is simple and cheap.

- Complete water bottling machine just cost $8500.

- It is very mature machine that over 30years.

- Every spare part quality is good.

Washing, filling and capping are rotate. So every unit running do not need stop and waiting other machine working. It is continued running and speed is the really capacity.

Start bottled water business with low-invest

12-12-1 Linear water bottling machine has been a reliable starting point for many bottled water companies. It serves as an entry-level solution, allowing businesses to initiate their operations efficiently. Here are some key points to consider:

- Ideal for Startups: Many bottled water companies start bottle water business from this machine due to its simplicity and cost-effectiveness. It provides a easy complete solution for those starting from scratch in the bottled water industry.

- Longevity: Some bottled water companies continue to use this machine for over two decades, indicating its durability and reliability.

- Familiarity: Workers and engineers fast familiar with its operation and maintenance, making it a preferred choice for businesses with established expertise in managing this equipment.

- Simplicity : The machine’s simplicity make it an attractive option, especially for businesses looking for cost-effective solutions.

- Affordability: While it may have limitations in terms of speed and space efficiency, its straightforward design serves its purpose for smaller-scale operations.

- Considerations:Take into account the machine’s limitations, such as slower speed and space requirements, when planning for production scale and efficiency.

In summary, the 12-12-1 Linear water bottling machine has played a crucial role in the growth of bottled water businesses, offering a reliable and accessible solution for those entering the industry. Its continued use in the market demonstrates its lasting impact and value for certain operational contexts.

How This bottling machine working in an complete bottling plant?

A water bottling machine in a complete water bottling plant typically goes through several stages to rinser, filler and capper water bottles.

After bottle been maked by blowing machine, worker need fast send it to water bottling machine. So it can fast washing at once and filler pure water, Then finished the capper seal. The process reduce the bottle been pollution by the envorenment to make sure the pure water quality.