fob price $16,000.00

What this price of Water Soda Bottling Machine included?

1. 8-8-3 washing filling capping machine balance pressure filling

2. Air conveyor 2 meter with fan, Conveyor belt 2 meter with motor

3. Auto cap loading and feeding equipment

4. Gas and water mixer.

Best all inclusive soda bottling machine collect washing, filling and capping in one monoblock bottling machine. This soda water bottling machine is widely use for bottling soda water, sparkling water and carbonated soft drinking.

Since the pressure in the bottle to be filled before and after filling is equal to the pressure in the bin and greater than atmospheric pressure. It is called balance pressure filling.

It can reduce the loss of carbon dioxide contained in the product and prevent excessive foaming during the filling process from affecting the product quality and quantitative accuracy.

| Capacity of production | 1500 bottles per hour Washing Head Quantity: 8 Filling Valve Quantity: 8 Capping Head Quantity: 3 |

| Filling Temperature: | 2-5 Degree |

| Shipment container | 20ft container |

| Machine Weight | 1600kg |

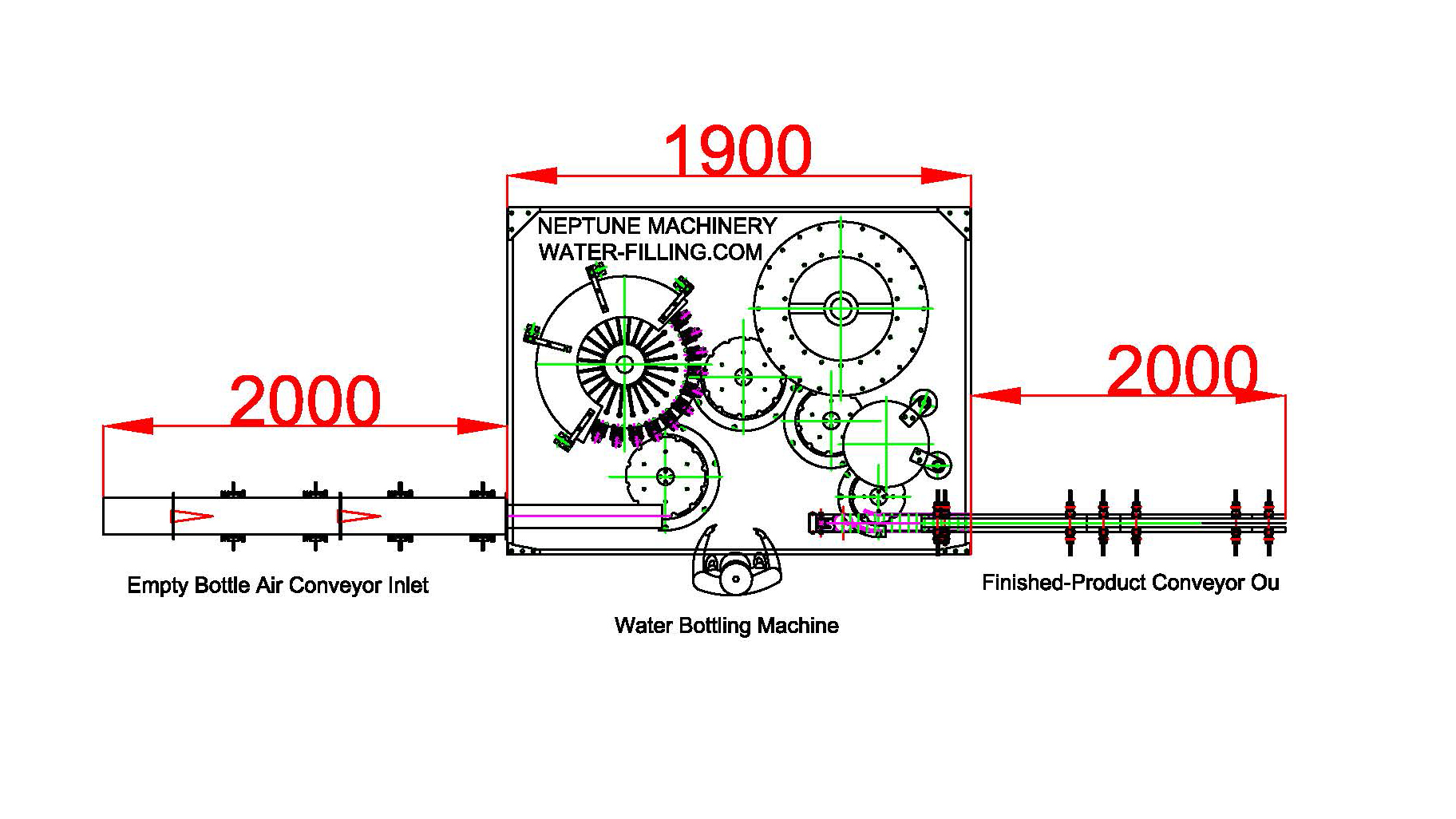

layout of the water Soda bottling machine

883 Bottled Soda water filling machine aim at 2000bph capacity, so that just fit 8 psc filling head, 8 psc washing head and 3 psc capping head. It save materials cost so that the soda bottling machine for sale price is cheap.

Every valve finished working on one bottle and will moving to next bottle around the 360 degree disk. It is continued working without any stop.

It is fully automatic soda filling machine which save worker labor. It is easy use and control by PLC. It is the new soda water bottling machine. Little-know way to increase filling efficiency with less cost.

Inside of the soda water bottling machine monoblock

883 pet bottle soda filling machine is a monoblock type soda bottling machine collect rotary rinser, filler and capper in one machine. It take small room.

- Every rinser head is moving synchronously with bottle while washing the plastic bottle. It working around 360 degree disk.

- Every filler head is moving synchronously with bottle while filling water into the bottle. It working around 360 degree disk.

- Every capper head is moving synchronously with bottle while capping the bottle water. It working around 360 degree disk.